|

Underlying physics

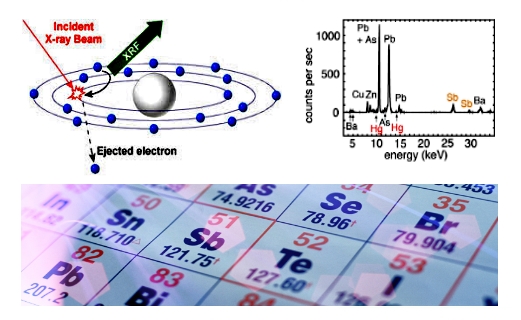

When materials are exposed to short-wavelength X-rays

or to gamma rays, ionization of their component atoms may

take place. Ionization consists of the ejection of one or more electrons from

the atom, and may occur if the atom is exposed to radiation with an energy

greater than its ionization energy.

X-rays and gamma rays can be energetic enough to expel tightly held electrons

from the inner orbitals of

the atom. The removal of an electron in this way makes the electronic structure

of the atom unstable, and electrons in higher orbitals "fall" into the lower

orbital to fill the hole left

behind. In falling, energy is released in the form of a photon, the energy of

which is equal to the energy difference of the two orbitals involved. Thus, the

material emits radiation, which has energy characteristic of the atoms present.

The term fluorescence is

applied to phenomena in which the absorption of radiation of a specific energy

results in the re-emission of radiation of a different energy (generally lower). |

|

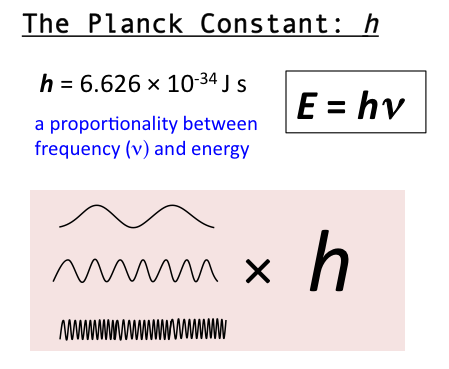

Characteristic radiation

Each element has electronic orbitals of characteristic energy. Following removal of an inner

electron by an energetic photon provided by a primary radiation source, an

electron from an outer shell drops into its place. There are a limited number of

ways in which this can happen, as shown in Figure 1. The main transitions are

given names: an L→K transition is traditionally called Kα, an M→K

transition is called Kβ, an M→L transition is

called Lβ, and so on. Each of these transitions yields a fluorescent

photon with a characteristic energy equal to the difference in energy of the

initial and final orbital. The wavelength of this fluorescent radiation can be

calculated from Planck's Law:

-

The fluorescent radiation can be analysed either by sorting the energies of the

photons (energy-dispersive analysis) or by separating the

wavelengths of the radiation (wavelength-dispersive analysis). Once sorted, the intensity

of each characteristic radiation is directly related to the amount of each

element in the material. This is the basis of a powerful technique in analytical chemistry.

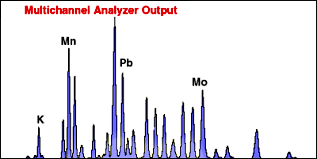

Figure 2 shows the typical form of the sharp fluorescent spectral lines obtained

in the wavelength-dispersive method (see Moseley's law).

|

|

|

Dispersion

In energy dispersive analysis, the fluorescent X-rays emitted by the material

sample are directed into a solid-state detector which produces a "continuous"

distribution of pulses, the voltages of which are proportional to the incoming

photon energies. This signal is processed by a

multichannel

analyser (MCA) which produces an accumulating digital spectrum that can be

processed to obtain analytical data.

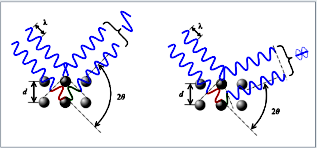

In wavelength dispersive analysis, the fluorescent X-rays emitted by the

material sample are directed into a diffraction grating monochromator. The

diffraction grating used is usually a single crystal. By varying the angle of

incidence and take-off on the crystal, a single X-ray wavelength can be

selected. The wavelength obtained is given by the Bragg Equation:

-

where d is the spacing of atomic layers

parallel to the crystal surface.

|

Chemical analysis

https://en.wikipedia.org/wiki/Beryllium

The use of a primary X-ray beam to excite fluorescent radiation from the sample

was first proposed by Glocker and Schreiber in

1928.[3]

Today, the method is used as a non-destructive analytical technique, and as a

process control tool in many extractive and processing industries.

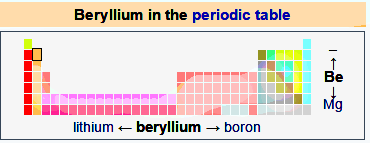

In principle, the lightest element that can be analysed is beryllium (Z

= 4), but due to instrumental limitations and low X-ray yields for the light

elements, it is often difficult to quantify elements lighter than sodium (Z

= 11), unless background corrections and very comprehensive inter-element

corrections are made. |

|

Metal Analyzer

http://www.spectro.com/products/mobile-metal-analyzer

|

|

|

|

Mobile metal analyzers have been used for over 30 years

to conduct metal analysis onsite. The rapid development in instrument technology

has led to significant advances in the application possibilities.

The current range of applications for mobile metal analyzers far exceeds the

original, yet still critical, steel mill sorting requirements. Demanding metal

analysis tasks such as the laboratory-like analysis of complex alloys or the

detection of nitrogen in duplex steels highlight the modern capabilities of

on-site metal analysis.

|

|

|

|

Working principle

Arc spark OES (spark OES) is the analysis method used by portable and mobile

metal analyzers.

The principle of the analysis method portable and mobile metal analyzers is

optical emission spectroscopy (arc spark OES or spark OES).

Sample material is vaporized with the testing probe by an arc spark discharge.

The atoms and ions contained in the atomic vapor are excited into emission of

radiation. The radiation emitted is passed to the spectrometer (arc spark OES)

optics via an optical fiber, where it is dispersed into its spectral components.

From the range of wavelengths emitted by each element, the most suitable line

for the application is measured by means of a CCD.

The radiation intensity, which is proportional to the concentration of the

element in the sample, is recalculated internally from a stored set of

calibration curves and can be shown directly as percent concentration.

|

|

Handheld XRF Spectrometers Key

Features:

Silicon PIN (S-PIN) detector:

-

Get grade identification of metals in seconds.

-

Including an ultra-simple pass/fail sorting mode, Ideal for the quick incoming

inspection of materials.

Silicon drift detector (SDD):

-

Provides reliable, highproductivity measurement and analysis.

-

Get metal grade analysis in only 2 seconds for most alloys.

-

Only 7 seconds for difficult light elements containing alloys, such as aluminum,

magnesium, silicon, phosphorus, and sulfur.

-

Ideal for scrap metals sorting, positive material identification (PMI), and more

Largest silicon drift detector (SDD):

-

Helps provide reliable measurement and analysis of nonmetallic materials.

-

With an outstanding level of performance.

-

High-productivity spot checks in a few seconds.

-

Hold on the sample longer for laboratory-quality ppm results.

Ideal for environmental and RoHS compliance screening, as well as for geological

exploration and more.

Common features:

-

X-ray safety gasket to

prevent backscatter radiation from light": element matrix samples.

-

Optional integrated GPS

receiver.

-

S-PIN detector(on xSORTAlloy

only) or high-resolution, high-sensitivity SDD.

-

Easy-to-use wireless LAN to deliver, results anywhere on network.

-

Users can view and manage results or collaborate remotely and archive the

information.

-

Ouick-change battery.

-

One-sample, one-time automated standardization system.

-

Low detection limits - down to ppm range for heavy metals and now even

light elements.

-

Optional integrated video camera for precise spot testing, with

visual memory storage.

-

Interface bezel with operator-defined hotkeys to maximize speed of common

tasks.

-

"Live" analysis results (display updated every few seconds).

-

Simplified software featuring:Touchscreen interface with only two menu

levels-intuitive ease for highest productivity.

More Handheld XRF Spectrometers Key Features .....

Portable XRF Spectrometers Key Features:

-

Portable, energy-dispersive X-ray fluorescence (ED-XRF) spectrometers Bring

lab-grade analysis into the field or onto the production floor.

-

Deliver much of the analytical power of top-grade laboratory benchtop analyzers.

-

Provide fast, dependable, truly lab-quality results in the field or on the

production floor.

-

All at a surprisingly low cost.

-

Provide exceptional performance, at wide concentration levels.

-

For all of the relevant elements in the range of Na - U.

-

Ideal portable XRF for onsite applications where results matter.

-

Available in two versions for field & offsite testing or laboratory & at-line

testing.

-

Simplified software is accessed via a touchscreen interface. Predefined

application packages are designed to fit the task at hand.

-

Unique iCAL calibration takes just one sample and only five minutes for

standardization.

-

Optional integrated video system allows precise spot testing, plus image

storage.

-

Optional global positioning system (GPS) adapter.

-

Predefined application, packages designed to fit the task at hand. Large sample

compartment.

-

Silicon drift detector(SDD), available for precious metal Version Si-PIN.

-

Element range from sodium to uranium (for precious metal version, application-specific).

-

Helium purge or vacuum to access light elements such as sodium and magnesium.

-

High-yield battery pack (standard for offsite, optional for at-line)

More Portable XRF Spectrometers Key Features .....

Small Spot XRF Spectrometers Key Features:

-

The market recognized gold standard for precious metals analysis.

-

Widest scope of elements backed by extensive factory calibrations providing the

best accuracy for traces and majors.

-

Fastest measurement times: choose exceptional results at conventional

measurement times, or conventional results at exceptional measurement times.

-

Precious metal, compliance, element line scans and mappings testing

optimizations.

-

Smart alternative to fire assay for elemental analysis.

-

Latest high-spectral-resolution detector technology, greatly improved count

rate.

-

Most advanced midrange comprehsive midrange laboratory XRF benchtop analyzers.

-

Regulatory compliance, fast screening of elements as chromium,bromine, cadmium,

mercury, and lead.

-

Optional collimator changer varies the spot size to fit the required analysis

area.

-

Ultra-fast large-area mapping with Optional XYZ sample tray with maximum 4 x 4

mm spot size.

-

Areas of concern can then be analyzed in detail with a smaller spot.

-

From tiny fragments to larger gunshot residues mapping in forensics science.

-

High precision, accuracy, wide concentration levels, and very shorttimes for

precious alloy(often 30-40 seconds).

-

For small jewelry items or drill cuttings from remelted samples: it analyzes a

small spot (typically 1 mm).

-

For Silver samples, which may be relatively inhomogeneous, averaged results from

an optional larger spot size maintain high-accuracy results.

-

Proprietary fundamental parameter method for alloy testing.

-

Optimized RoHS calibration covering a wide range of elements and matrices.

-

Fast point analysis can determine concentrations of typical and important

elements for unknown samples. (in the range from magnesium to uranium in less

than 180 seconds).

-

Spacious chamber features a large, easy-access opening for sample placement and

removal.

-

Integrated video system aids in exact measurement positioning, especially for

line scan and mapping.

-

Optional 20 mm working distance permits focusing on irregular shapes sample

points.

-

Optional motor-driven XYZ table enables line scans and mappings of large sample

surfaces.

-

The XYZ Table can also be used as sample plate for automatic test of large

numbers of samples.

-

One of the fastest XRF mapping systems commercially available.

-

Mapping of a Eurocard-format double PCB can be completed in less than 30

minutes.

-

Relevant areas can then be rescanned with even higher spatial resolution.

-

Intuitive software supplies all relevant information on a single screen, guiding

the user through each task.

-

Display, printout, and transfer of analysis results, support later data use

and/or proof of compliance.

-

Cost-effective with accuracy and speed than costly additional fire assay, or

ICP-OES testing that requires digestion.

-

Global Performance Services program with more than 200 service engineers in 50

countries.

-

High-value, customized services, include proactive maintenance programs,

application solutions, access to specialists, and instrument-specific training,

etc.

More Small Spot XRF Spectrometers Key Features .....

3x Improvement XRF Spectrometers Key Features:

-

Up to 3x improvement: Precision, accuracy for trace elements and major

components.

-

Measure lower than ever: Adaptive excitation, advanced tube design, high-count

throughput.

-

Time is on your side: Exceptional sensitivity and precision or measurement times

conventionally parrelled.

-

Master the unknown: Unprecedented software tool ability to analyze most unknown

samples.

-

Software designed with users: Easiest to use and most powerful yet.

-

Faster measurements: Meeting speed oriented applications maintaining traditional

ED-XRF precision levels.

Unprecedented affordability:

-

Significantly lower investment cost than wavelength dispersive X-ray

fluorescence (WD-XRF) spectrometers.

-

Get WD performance at an ED price !

-

Perform on equal terms with much more expensive WD-XRF technology for many

applications.

-

Low-volume helium purging for light elements in liquids and powders.

-

Vacuum system for solid samples.

-

Advance predefined craft configurations for prioritize measurement requirements.

Rethinking the X-ray tube:

-

One potential weakness of traditional ED-XRF designs: cycling power off between

each measurement, resulting temperature variations inevitably decrease signal

stability, especially with the higher count rates of WD-XRF and newer ED-XRF

instruments, this can complicate analysis, add error, and degrade accuracy.

-

Employs a new aircooled end window X-ray tube.

-

Brighter, laboratory-quality excitation source optimized for maximum energy

generation.

-

Remains powered up, even between measurements, avoiding the instability of

constant on/off cycling.

-

New thick-target, revolutionary binary cobalt/palladium alloy anode design.

-

Extra sensitivity and lower LODs for specific element groups.

-

Fully realize in lower LODs, higher sensitivity, minimal matrix effect impact.

-

Exceptional accuracy for concentrations - both high and low.

-

Attaining substantially longer tube life.

Introducing adaptive excitation :

-

Unique revolutionary new adaptive excitation technology, enabled by new

high-resolution detector and readout system.

-

Contribute to ultra-high sensitivity and minimal background interference, for

greater precision and lower LODs.

-

Precisely configured to produce high sample throughput or best precision for

target application orientations.

-

Optimum excitation conditions for a specified group or groups of elements.

-

The X-ray beam is optimized by fixed excitation optics with different beam

channels.

-

Combined polarized/direct excitation - For optimum analysis of light medium, and

heavy elements.

-

Band-pass filter excitation - first commercial utilization of band-pass filter

for extra performance in the K to Mn range.

Redesigning the detector :

-

New silicon drift detector (SDD) design.

-

High resolution with low spectral interference.

-

Enlarged surface (30 mm2) with maximized active area (20 mm2).

-

High-speed readout, combined ultra-high count rate - up to 1 million counts per

second (cps).

-

Resolution contributes greatly to improved peak-to-background ratios, extremely

low LODs, and ultra-high sensitivity.

-

Even smaller peaks emerge from the background.

-

Excellent limits of detection in a wide range of matrices. Simple yet

sophistical software

Software interface :

-

designed and optimized with third-party testing and benchmarking.

-

Extensive user input & feedback to be exceptionally easy to learn and use.

-

Clearly separated modules offer optimized access to critical information.

-

Once calibrated, routine analysis is a snap.

-

An array of optional precalibrated application packages, meets many users'

needs.

-

Lab managers may request their own application-specific configurations.

-

Standard analyses cover elements in the range from sodium to uranium.

Analyze:

-

Lubricating oils, low-sulfur fuels, Polymers, Chemicals, Air filters,

Clinker/cement/slag, Geological samples, Ceramics and refractories, Cosmetics,

Foods pharmaceuticals, Steel and aluminum sheet coatings, Environmental samples

like soil or sewage sludge, and more.....

Exemplary ease of Use:

-

Superb analysis of unknown samples.

-

Dramatically improved, more flexible, best-in-class software tool, available.

-

Unmatched screening unknown samples for elements from sodium to uranium, without

extensive setup.

-

Handles an even greater range of samples.

-

Including any type of liquids, plus solids from tree leaves to plastics, granite

to glass - with a single calibration.

-

Conquers matrix effects (even at low concentration levels), achieves

breakthrough speed and precision, and handles previously impossible

applications.

-

Supplies screening results in a few minutes.

-

Maximum flexibile versatile sample compartment

-

ED-XRF requires little sample preparation relatively to ICP or AAS.

-

Makes sample handling more convenient than ever.

-

Spacious 372 mm (14.6 in)x253 mm (9.9 in) X 45 mm (1.8 in) measurement

compartment.

-

Accepts an optional sample tray with up to 25 positions for maximized

productivity.

-

Accommodates direct analysis of large and/or irregular-ly shaped samples.

-

Permits analysis of light elements in powders with optional low-consumption

helium purge.

-

Optional vacuum system for economical pressed powder pellets, fused beads, or

solid samples.

-

Optional for both capabilities in a single unit.

Extensive elemental analysis solutions lines :

-

Small-spot, powerful portable and hand-held lines.

-

Complemented by ICP-OES, such as the top-of-the-line, compact midrange, and

"plug-and-analyze".

-

Full lines of both stationary and mobile metal analyzers.

Ultimate confidence with remote monitoring :

-

Extend & Integrate the instrument's self-diagnostic functions with our WLAN

monitor & service system.

-

Including remote monitoring with ongoing diagnostics and alerts.

-

Machine-to-machine support allows proactive alerts, backed up by direct

connection with a remote service expert's PC.

-

Ultimate in quick, sure response and resolution, ensuring uptime service .

-

Help make certain and keep up and running for maximum productivity.

-

More than 200 service engineers based in 50+ countries can safeguard

uninterrupted performance.

-

Maximum ROl over the instrument's entire service life.

Proactive support :

-

Performance maintenance, Performance upgrades, Application solutions,

Consultation, Targeted training, Ongoing support.

More 3x Improvement XRF Spectrometers Key Features .....

XRF Spectrometers Application Report List:

*** Please login to request anapplication report

|