|

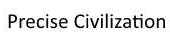

Micro Reactor

MicroReactors offer many advantages over

conventional scale reactors,

including vast improvements in

energy efficiency, reaction speed and yield, safety,

reliability, scalability,

on-site/on-demand production, and a

much finer degree of process control.

Using MicroReactors is somewhat different from using a glass

vessel.

These reactors may be a valuable tool in the hands of an

experienced chemist or reaction engineer.

Microreactor combines with micro mixing chip, micro heat

exchanger chip, micro flowing chip etc.

With its unique structure, it can quickly endothermic,

exothermic, heat up, mass transfer and others.

Depending on different reaction, it can divide into

liquid-liquid reaction,

gas-liquid reaction and gas-gas phases

reactions.

Using precision machining technology to

produce specific channels in 10 to 500 microns ID sizes,

with the common

characteristics of chemical reaction in a small space.

The average size of the channel is

generally micron or nanometer, and with tens of thousands

channels contained inside that can

achieve a very high yield.

The

Characteristic of MicroReactors:

1. Continuous reaction, time saving, small footprint

2. High precise controllability, surface area, fast heat and

mass transfer efficiency

3. Safe and reliable, sealed, small moment holdings

4. Less byproducts, reduce pollution, low environmental costs

5. No amplification effect, reducing the pilot variations,

shorten development cycle

6. Wide operating range, suitable for a variety of reactions

7. Intergated device, quick installation

8. Stable quality

Leading with Quality, Performance and Cost

Our partners, the FRAPP'S Chemical

Industrial is a high-tech enterprise that focuses on research

and

production of the Pneumatic Driving Pressure Filter with

independent intellectual properties,

that based on the

integration and refining of the global research and engineering

practice.

Our main equipments is for mixing, reacting, synthesizing,

extracting process in the chemical production

technologies, in

the fields like phosphorus chemical industry, petroleum chemical

industry,

fine chemicals and so on.

We also have advanced technology on dust-free cooling equipment

of solid particles, powder materials.

www.frappsbio.com

Product R&D

process comparison

|

|

Microchannel

Reactor |

Conventional

Reactor |

|

Application span |

Specific

reaction |

Generic

application |

|

Continuity |

Continuous |

Batch |

|

Heat transfer efficiency |

High |

Low |

|

Control and condition |

Precise |

Difficult |

|

Efficiency |

High |

Low |

|

Materialv distribution |

Uniform |

Non-uniform |

|

Byproduct |

Low |

High |

|

Security |

High |

Low |

|

Initial Cost |

High |

Low |

The main materials of

Microchannel Reactor are Titanium, Zirconium alloys and

Hastelloy.

The three-dimensional structure element for carrying

out the chemical reactions is based on

solid matrix and produced

by special micro-processed technology, that can largely increase

the surface

contact probability, and enable adequate reaction of the

raw materials.

Suitable reactions:

Sulfonation, Methylation,

Hydrogenation, Nitration, Oxidation, Esterification,

Diazotization reactions.

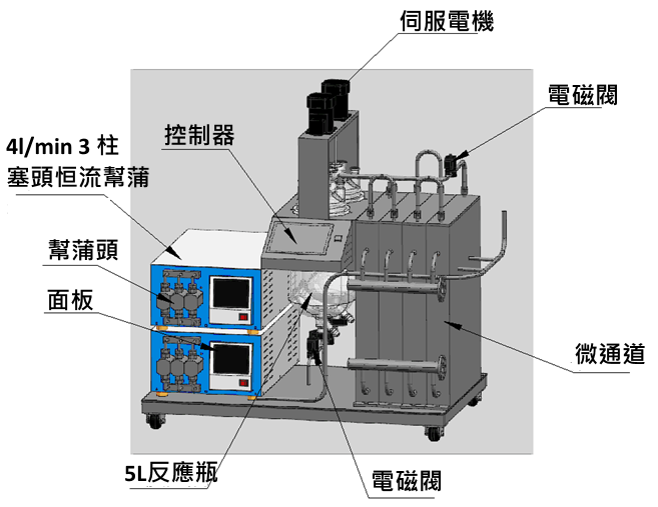

Schematic diagram: Fixed bed

debenzylation

Diazomethane

Applications

Click to enlarge

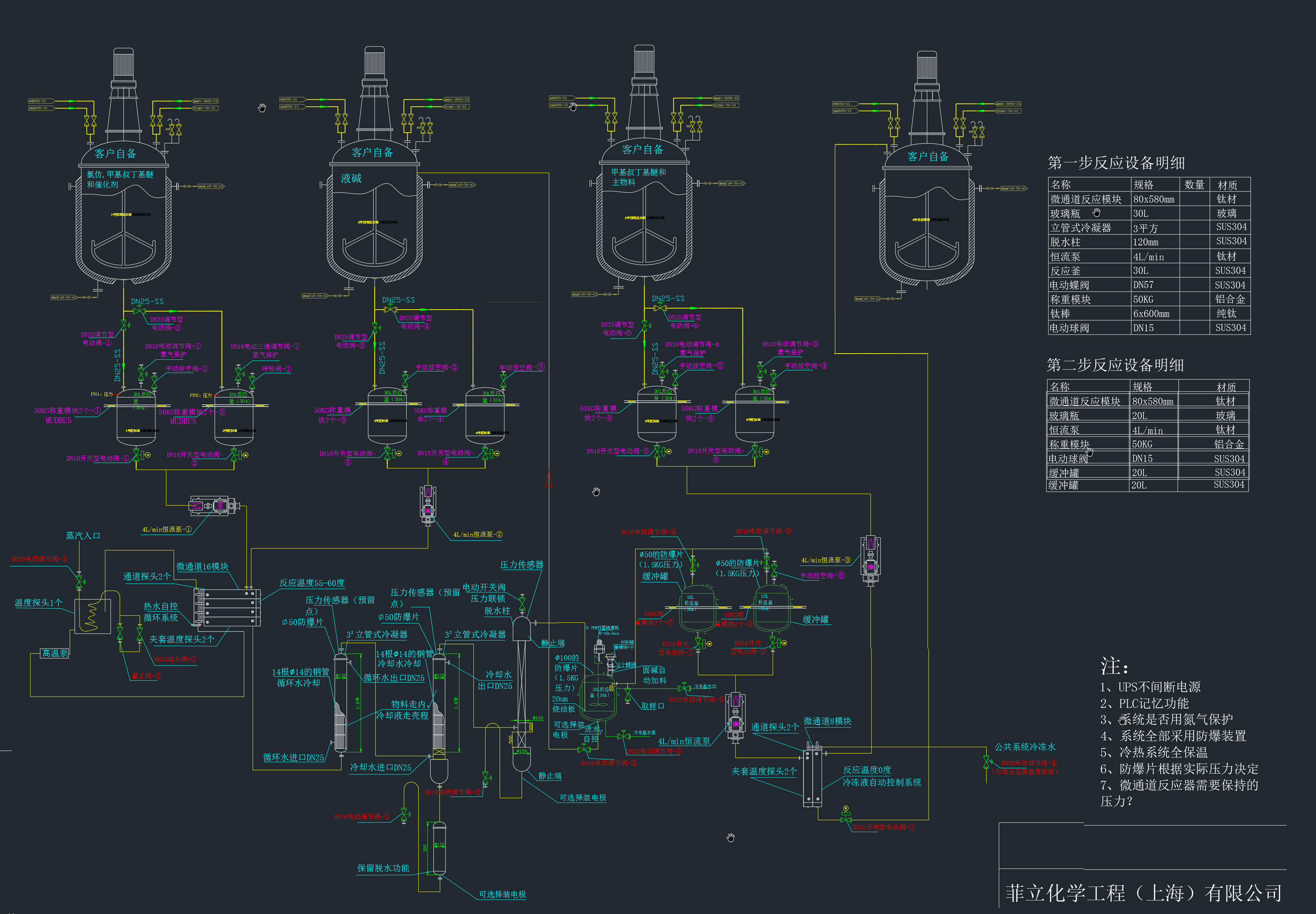

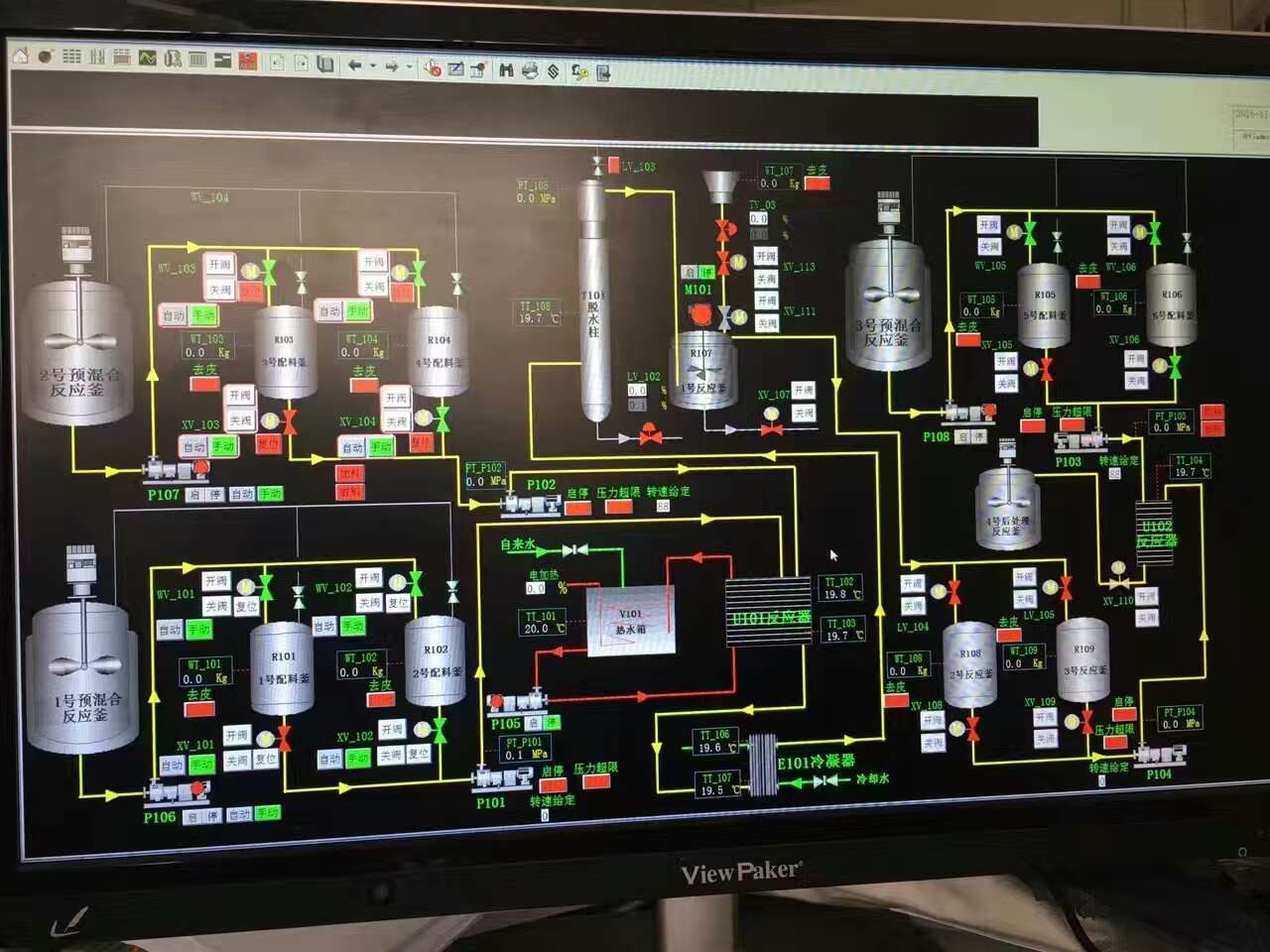

Procedure example:

1. Add Chloroform, methyl tert-butyl ether and catalyst

into 3000L, No.1, premix reactor, stirring until clear, and prepare for use.

2. Put Caustic soda into 3000L No.2 premix reactor , and prepare for use.

3. Methyl tert-butyl ether and the main material was dissolved in 3000L, No.3

premix reactor, and prepare for use.

4. Using two sets of 30L No.1 and No.2 stainless steel Material Preparation

reactors that are equipped with weighing modules, first put 25KG material into

the No.1 Material Preparation reactor, then after completion, immediately switch

to No. 2 Material Preparation reactor for reparation, and start the isocratic

pumps, conduct material form No.1 Material Preparation reactor into the

microchannel, after completion of the feed when the scale of weighing module is

lower than 50 to 80 grams,it will automatically switche to the No.2 Material

Preparation reactor and proceed in sequential loop. On the outlet of No.1 and

No.2 Material Preparation reactors,there are DN10 electric switch valves

equipped for system nitrogen protections。

5. Using two sets of 30L No.3 and No.4 stainless steel Material Preparation

reactors that are equipped with weighing modules, first put 25KG material into

the No.3 Material Preparation reactor, then after completion, immediately switch

to No. 4 Material Preparation reactor for reparation, and start the isocratic

pumps, Conduct material form No.3 Material Preparation reactor into the

microchannel, after completion of the feed when the scale of weighing module is

lower than 50 to 80 grams,it will automatically switche to the No.4 Material

Preparation reactor and proceed in sequential loop. On the outlet of No.3 and

No.4 Material Preparation reactors,there are DN10 electric switch valves

equipped for system nitrogen protections。

6. The microchannel reactor temperature was set at about 70 ℃, the reaction

temperature is controlled at 55-60 ℃.

7. Reacted material is cooled through water(a 3 square vertical tube condenser)

and refrigeration brine(a 3 square vertical tube condenser), and then dehydrated

with electric control valve equipped at the bottom to automatically discharge

water.

8. Using a 30L small reactor equipped with a sintered plate and stirrer, add

into 10KG sodium hydroxide, conduct the dehydrated reaction liquid from into the

bottom to dehydrate with sodium hydroxide again, and then go out from bottom

flange of the reactor. At the outlet, there is equipped with a 6*300 Titanium

rod filter to prevent from flowing out of sodium hydroxide together with the

material. Two DN57 electric butterfly valve is equipped in serial at the top of

the reactor for adding sodium hydroxide. Sodium hydroxide is put between the

valves when the upper electric valve is opened, and then the upper electric

valve is closed before the openning of the lower electric valve, ,thus

preventing the diazomethane gas from leakage.

9. The dehydrated reaction liquid is conducted into a 10L buffer tank, and ,

when the filled material reaches top limit point, start 3# isocratic pump, and

in the same time, start 4# isocratic pump to pump materials form #3 Material

Preparation reactor into the microchannel for reaction, with microchannel

reactor temperature at 0 ℃. The reacted material flows back to the reactor for

further processing.

|